| << . 1 . 2 . 3 . 4 . |

| Author |

Message |

DRP

Member

|

# Posted: 14 Oct 2025 08:34pm

Reply

I went in this morning and asked Alexa to play "oldies". She said "The play list 70's music coming up". I muttered "That ain't oldies". She muttered back "OK boomer" . .

In the late 50's /early 60's the Forest Products Labs was working on several research projects. One group created "Impreg", wood impregnated with some goo or other to strengthen and stabilize it. "Compreg" was another, compression and impregnation. The results were impressive, never seen either make it to market. There have been numerous others through the years, the silica impregnated fireproof stable wood, etc Hope for the best but price pressure is brutal. I imagine this is also more fire retardent at that high density. Like many dense jungle woods, probably need to predrill fasteners.

I imagine the teacup is check prone in that orientation, but really any orientation that uses the whole diameter of the stick. I guess basically it holds true, if the heart is in it, its probably a high risk stick.

|

|

DRP

Member

|

# Posted: 26 Oct 2025 07:29am

Reply

I sawed some overripe pine logs yesterday and got into more pine sawyer grubs. Far better to fell and saw quickly, these sat all summer and became bug food. I thought I was making an 8x8 post but decided after showing the damage to just keep sawing boards for lumber pallets.

URL

|

|

MtnDon

Member

|

# Posted: 26 Oct 2025 03:12pm

Reply

Noisy.

Opportunistic hungry bug-gers

|

|

DRP

Member

|

# Posted: 31 Oct 2025 08:29pm

Reply

I think I did some stuff this week that will tie some loose ends together.

A poster asked about moisture content when things were "dry" in a green shell so he could apply finishes.

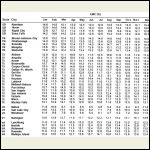

I pointed to this reference which gives Equilibrium Moisture Content for Wood around the world:

https://www.fpl.fs.usda.gov/documnts/fplrn/fplrn268.pdf

Look below, I'll find the table for the area closest to me. I broke into a pile yesterday, took it to work and metered it... let's see how close it is to the table. I actually don't know yet either, but its usually pretty close. I'm closest to Roanoke, VA, the wood is from Oct/ Nov, so air dry emc should be about 12.5%

Second pic is my stacks, I build pallet roofs to cover the piles, air dried but mostly not rain wetted... outside air under cover as per the tables.

Last pic is my meter in one of the boards off that open middle stack of 2x6's. The wood is fully air dried and at equilibrium with its environment, neither gaining nor losing moisture... the definition of the tables equilibrium moisture content.

Pretty darn close depending on which side of the mountain you're on, the science works.

And it was a pretty evening, he took me for a walk to the back 40.

EMCtable2.jpg

|

PileCovers.JPG

|

EWP.EMC.JPG

|

Quarry.JPG

|

|

|

MtnDon

Member

|

# Posted: 31 Oct 2025 10:10pm

Reply

Quoting: DRP the science works.

|

|

MtnDon

Member

|

# Posted: 1 Nov 2025 03:30pm

Reply

I make assorted stuff from wood; stuff smaller than a cabin. Mostly for fun and a lot of things become gifts.

Here's an example. This used to be a short piece of S-P-F 2x6. After a glue-up and some time on the lathe it is about 4-1/2"diameter x 2-3/4" high.

|

|

DRP

Member

|

# Posted: 2 Nov 2025 08:58am - Edited by: DRP

Reply

That's cool, the few times I've turned softwood it didn't end well. The most memorable was a cannonball bed post that popped off the centers. It rolled up one side, hit me in the head and rolled down the other, beat up by the ugly stick  . Were you in a chuck or on a faceplate, or ? . Were you in a chuck or on a faceplate, or ?

|

|

MtnDon

Member

|

# Posted: 2 Nov 2025 10:37am - Edited by: MtnDon

Reply

Start with a faceplate on the end that becomes the top. Turn the general outside shape and create a tenon for the chuck to grab at the other end.

Remove from the lathe. Remove faceplate. Install the 4 jaw chuck on lathe. Insert tenon into the chuck and close the jaws. Clean up the outside as the chuck centering is likely to be a slight bit different than the faceplate was.

Mount the drill chuck in the tailstock and bore a center hole almost as deep as the bowl interior finished dimension will be. Use a bowl gouge or carbide scrapers to hollow out the bowl.

Reverse the lathe direction and sand inside and outside. Grits 80, 120, 150, maybe 180. Softwood needs a lot more sanding than hardwoods.

When completed I secured the tenon end in the bench wood vice and used an Japanese pull saw to cut it off, then sanded the bottom on the bench sander. There is another way to use a jam chuck and the tailstock live center to remove the tenon with lathe tools, but I need to repair that jam chuck. Besides the softwood was easy to saw off.

There is also a jaw set (Cole's jaws) that can be used to grip the rim of the bowl with the tailstock used to hold pressure against the headstock/chuck. But I don't have one of those.

Sometimes the tenon is left there and maybe shortened a little.

|

|

|

MtnDon

Member

|

# Posted: 2 Nov 2025 02:28pm - Edited by: MtnDon

Reply

FYI, here's a tenon from a different bowl. The 4 jaws of the chuck close and grip around it. This was a still wet chunk of wood; you can see how easily the jaws compressed the wet wood.

|

|

Aklogcabin

Member

|

# Posted: 3 Nov 2025 07:21am

Reply

DRP those are interesting charts. Back in the years I ran my little custom woodworking shop. I always had to consider wood movement. And how to deal with it. And where in the world it may end up.

When I was gluing up a large table or desk top. They could move 1/4" during different seasons. I learned to use a sprung joint. Basically this. Say I'm doing a 4'×8' solid top table. And have 4' long glue joint. I will set my joiner up so it will cut the edges and leave a 1/8"-3/16" gap in the center. Ends touching. This creates a greater compression on the ends. This will help insure that the end grain won't eventually dry enough to split. I would buy1000 bd.ft at a time. Rough cut grade A. 8% moisture. And had to deal with a lot of crooked wood. Making the bows work against each other. One way then the next. And never used boards wider than 3" to maintain control of warp.

When turning on the lathe. After turning. Grap a handful of the shavings. Hold them against the turning spindle in the lathe. This is what I was taught burnishing is. The friction will heat the lignin in the wood cells and give you a nice finish.

I got into starting a wood shop because I just liked wood. And wanted to become a good custom furniture builder. Did a lot of really beautiful stuff. Kitchen cabinets if they let me get custom. Office desks. Bookshelves. Anything that customers could think up. Get up every day n go build something from wood. Did that for over 10 years.

Just walking through the woods n looking at every tree is enjoyable.

|

|

DRP

Member

|

# Posted: 16 Nov 2025 10:40am

Reply

It's Christmas tree harvest time here, they are leaving the county by the tractor trailer load, about 4,000 at a time. The trailers lined up at the packing house coming from the fields hold around 400 baled trees. The shade cloth structure is to store them between harvest and loading if they need to hold them for any time. Usually they are packing and loading. The season started around Halloween and ends Thanksgiving. The crews will then head south to set the strawberries that were started here last spring. They will return in time to plant next years berries and then into the trees again for planting shearing, spraying and then harvest. The country stores get a whole lot quieter after turkey day.

XmasTrees3.jpg

|

XmasTrees2.jpg

|  |  |

|

|

DRP

Member

|

# Posted: 18 Nov 2025 07:27am

Reply

This is a really good article on a year in the life of a pine tree... although it gets into a year in the life of any tree. The link I had went dead 20 years ago but just found another of his papers and backtracked, it's still out there, good stuff;

https://www.ltrr.arizona.edu/~hal/tyerlif3.pdf

|

|

DRP

Member

|

# Posted: 30 Nov 2025 11:24am - Edited by: DRP

Reply

I think I showed the damage from oak timberworm a few pages ago. sort of a shotgun blast of holes of different diameters. The mature female beetle drills/chews a hole with her very long proboscis and then turns around, drops her ovipositor in the hole and deposits several eggs. These hatch into larvae that chew straight across the tree, hit the far side, turn around and return to the same area. The smaller holes are on the trip out and the larger ones on the maturing larvae's return. I had this picture from an oak timberframe job. We came back from a break and she had come to do damage to my timbers! After roughing out the joinery we dropped the timbers in a site built dip tray full of a borate solution. The larvae would not survive. If you look it up on bugwood or similar, the end of that long snout has a pair of wood chomping pincers to excavate that egg cavity. She is hard at work.

OakTimberworm2.JPG

|

OakTimberworm.JPG

|  |  |

|

|

MtnDon

Member

|

# Posted: 1 Dec 2025 06:04pm

Reply

Interesting info and image.

The family of the logger we had do the tree removal after the wildfire has been involved in logging in our mountains since about 1915. He is more than just some guy who cuts trees; he has a forestry science degree. He has some audio clips of White-spotted Sawyer Beetles doing their thing; a scrape - scrape - scrape sound.

|

|

DRP

Member

|

# Posted: 11 Dec 2025 12:16pm

Reply

I've been enjoying this wood selection chapter of a 1920 Navy manual on airship construction. This was the era of wood and cloth, and what wood they were calling for!

https://www.loc.gov/resource/gdcmassbookdig.airplanesairship00tuck/?sp=71&st=image

|

|

DRP

Member

|

# Posted: 5 Feb 2026 07:19pm

Reply

Attached is a pic of a piece of rafter. Happily the carpenter was young and quick. I've always known this as brown cubic rot, brown rot (intermittent wet "dry rot") vs white rot (constantly wet).

https://extension.psu.edu/brown-rot-in-wood

|

|

paulz

Member

|

# Posted: 10 Feb 2026 03:17pm

Reply

The other day I picked up this chunk from who knows where and man, heavy as metal! My neighbor agreed, says it’s Iron Eucalypti. Skeptical I looked it up, really is such a thing.

|

|

gcrank1

Member

|

# Posted: 10 Feb 2026 06:53pm

Reply

I think that needs to be made into something 'special'

|

|

DRP

Member

|

# Posted: 10 Feb 2026 08:05pm

Reply

I think there are more eucalypts than oaks, well, looks like 742 species, and they are all out of my range. Is it this one?

https://kalanihardwoods.com/pages/ironbark-eucalyptus

If so I agree, it sounds like turning might be a good use if the size is amenable.

I like this site, you can go way down rabbit holes  , this is his opening page on eucalypts; , this is his opening page on eucalypts;

http://hobbithouseinc.com/personal/woodpics/eucalypts.htm

|

|

| << . 1 . 2 . 3 . 4 . |