|

| Author |

Message |

philpom

Member

|

# Posted: 5 Dec 2025 07:39pm - Edited by: philpom

Reply

We started building many years ago but we did capture some photos along the way, I'll try to go back in time here a bit and update with new projects as they come along.

For disclosure, after looking back at some of the pictures, my timeline from my introduction post are a little off - time moves a little faster than I recall.

In 2007 we broke ground, had a road put in and terraced of a chunk of land from the hill. We built a 92' block retaining wall and backfilled that to create a nice level area for a future garden.

We trenched and boxed in a foundation for the wall, added rebar and filled with cement. We left long rebar runners out of the footer and stacked the blocks over those. Before we capped it we back-filled many of the voids with more cement. That was 18 years ago, the wall did develop 1 crack in it but it is stable, hasn't moved in many years. Once done we planted rye grass in the area to help with erosion, a nice grassy piece of yard at this point.

100_3816.JPG

|

100_3828.JPG

|

100_3805.JPG

|

img_3500.jpg

|

|

|

philpom

Member

|

# Posted: 5 Dec 2025 08:34pm

Reply

At the same time we put the wall in and had the dirt work complete we built the very first structure, the all important outhouse.

Before I go much further, I want to say, I am not a tradesman, never worked on a crew, I'm not a wood worker, and I only have basic tools. I don't build from plans, I make everything up in my head but I did take classes back in the day for framing both wood and metal and welding. I have been a handy guy that has completed many hundreds of DIY projects, I'm not afraid of anything weather an engine rebuild, breaker panel replacement, or a structure build. With that said, I may not always use conventional methods or materials. If anything I probably overbuild and I'm ok with that.

For me the outhouse had to be a double seater, at times back in the day we had large crowds out to the property and would run big tent cities for a week or more at a time. I dug the hole 6' deep, 4' long and 3' wide. The 4'x8' building had a stall on each end. The entire super structure is made from treated wood. The 4x4 posts were set directly in to the soil. The floor was a single sheet of true 3/4" marine ply, the heaviest piece of plywood I have ever handled! Can't have anyone falling through down the road was the thought.

I recall it was very hot on the days we built it, many of us took turns sitting on the bench determining the ultimate height for the bench. The cold air coming out of that hole felt amazing. We finished it with screen doors, a glass moon window and some good paint. That building still stands strong today with plenty of "capacity" left in it but it's for the guys only these days. I did replace the top of the bench and the seat a few weeks ago actually.

100_3841.JPG

|

100_3879.JPG

|

100_4984.JPG

|

100_4987.JPG

|

|

|

philpom

Member

|

# Posted: 5 Dec 2025 08:37pm - Edited by: philpom

Reply

More build photos of the outhouse. Skirting was trenched and built in to the dirt, back filled with soil and packed. The entire area was covered with gravel for a nice clean finish in the end.

Ended up so much better than a luggable loo. After 18 years even I am shocked how well it has held up. Once it reaches capacity we will likely convert it to a composting model. I have since framed in a bathroom inside but as stated in an earlier post, that's for the ladies.

100_4988.JPG

|

100_4991.JPG

|

100_4992.JPG

|

img_3422.jpg

|

|

|

philpom

Member

|

# Posted: 5 Dec 2025 10:19pm - Edited by: philpom

Reply

Fast forward 4 years, we had continued to tent camp on the land during this time but we had a horrible winter storm blow through the year before forcing us to abandon ship. Never again, the cabin build began. We built the foundation from 100% treated lumber to make sure there was never any rot. Using a gas powered auger we set 25 cement piers in the side of the hill. We put up a 24'x28' deck that would be home to a 24'x16' gambrel 2 story barn. Every joint had liquid nails plus deck screws. That was the foundation for the cabin. We ordered it from the local Lowes, their crew stood it up.

Both lower and upper cross framing were 2x10 treated lumber and the sub-flooring 5/16th treated ply. We insulated the cavity underneath.

IMG_6157.JPG

|

IMG_6176.JPG

|

IMG_6153.JPG

|

IMG_6150.JPG

|

|

|

philpom

Member

|

# Posted: 5 Dec 2025 10:48pm - Edited by: philpom

Reply

We took out the back half of the roof and extended it over the rest of the deck. This provided us a 12'x24' covered patio. We also added a deck on the front and worked it around the existing hickory trees. Those are as bad as a hail storm at certain times of the year.

We made heavy use of old railroad ties to shore up walk ways and frame out the gravel foundation for a 2 car carport. The carport was used for years as a material staging area, very useful. Now its great for parking and I have a few smokers under there. They get a new home soon.

It's starting to look much closer to the way it does today. I'll dive in to interior details in future posts. It has been a very long journey and it ain't over.

IMAG0149.jpg

|

IMAG0160.jpg

|

IMAG0153.jpg

|

IMAG0267.jpg

|

|

|

gcrank1

Member

|

# Posted: 6 Dec 2025 09:23am

Reply

When I saw the block work right off I thought this wasn't gonna be just a little weekend cabin.....

|

|

philpom

Member

|

# Posted: 6 Dec 2025 03:50pm

Reply

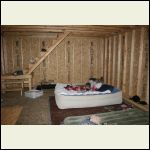

Up to 2015 now, progress was slower than I recall. We had young kids to deal with and we spent lots of time having more fun than anything else. For several years now the inside has been mostly unfinished. We did have the walls insulated and most of the interior sheathed. Our first wood stove was a cheap boxwood stove, put me back $125. Had to be stoked and fed every couple of hours but it kept us warm. A lot of meals were cooked on it, I still have the stove but don't use it. Eventually it will be placed in an outbuilding.

It always cracked me up that we spent nearly $1000 on chimney material to install this $125 stove. The good ole days.

|

|

philpom

Member

|

# Posted: 6 Dec 2025 03:54pm

Reply

I made the hearth by laying down cement pavers, then pieces of broken pavers to create an air gap, then a single piece of cement board and another full layer of pavers for the base. Behind the stove was cement board on the wall, then 1"x1" wood slats to create an air gap and that was finished over with corrugated tin. The back was purely functional, nothing fancy at all.

|

|

|

philpom

Member

|

# Posted: 6 Dec 2025 09:05pm

Reply

Quoting: gcrank1 this wasn't gonna be just a little weekend cabin.....

Funny thing, the original thought was very small, just a substitute for a tent and it grew and plans got more and more grandiose. It's still a small place, total square footage under roof is about 1000 but climate controlled is about 750. The kids have mostly moved on, only 2 left in the house. Eventually it'll just be the wife and I. Downstairs is one large room, a combo living/dining/kitchen with bathroom. Upstairs is the bedroom with sitting area.

|

|

gcrank1

Member

|

# Posted: 7 Dec 2025 09:00am

Reply

HaHa, our home for the past 38 years is only 940sf (was a late 1800's one room school) and cabin is 12x28. Someone once asked why we 'needed' a cabin when we have a cottage in the country already!

|

|

philpom

Member

|

# Posted: 7 Dec 2025 04:03pm

Reply

Quoting: gcrank1 HaHa, our home for the past 38 years is only 940sf (was a late 1800's one room school) and cabin is 12x28. Someone once asked why we 'needed' a cabin when we have a cottage in the country already!

Did you place the cabin in close proximity to the school house? I've seen some really neat multi buildi layouts where they have common decks, or even common covered areas.

|

|

gcrank1

Member

|

# Posted: 7 Dec 2025 05:00pm - Edited by: gcrank1

Reply

No, not 'close' but a lot closer to home than many; we have only a 45min drive to the cabin. It took us an off/on search for Years, often farther away then found this 'square' of 9+ac, mixed trees surrounding a lovely oak barrens meadow. The cabin sits basically in the center. Area is quiet, kinda hidden rolling terrain with town roads and Amish buggies. Closed on the property in Aug 2020. Iirc I joined here about 2019? This forum has been invaluable!

April of last year we tore down the original 16x24 sawmill board shack and brought in a custom prebuilt milled log 12x28 cabin with an entry overhang (keep that rain off getting in the door).

All totally off grid

I got too old and broken down to build our own this time but wife and I did hand build our 1st in 1883-84, a 12x24 with 12x12 sand up loft mostly from salvaged wood from the 1896 barn on the farm. 39 years on its still doing fine with the new owners since 2018.

|

|

philpom

Member

|

# Posted: 7 Dec 2025 05:56pm

Reply

Gotcha, for whatever reason I was thinking you put it on the same piece of land for more room. A getaway is nice and having a new project is fun.

Our cabin is a 7 hour drive from our fulltime home. The cabin itself is 45 minutes from a lumber store. This all combines and has made progress over the years a challenge. A 3 day weekend includes 14 hours on the road if I pull a trailer with materials, more if I need to go get materials. We have made a large amount of progress in the past 5 years which is amazing since I also built from the ground up a small camper trailer.

We originally purchased 20 acres but last year the 20 acres in front of us came up for sale so we bought that. Worked out perfectly because for 19 years our driveway passed through that 20 acres and had to reach out to the previous owners to create the right of way to get electricity to the cabin.

I assume you are using solar, what battery chemistry do you use and how many watts of solar do you have? For the camper I put in a small system, 100ah LiFePO4 battery and 200 watts of solar. Small but works very well for that application. Also included a 750 watt inverter but seldom use that. I have been specing out a larger system for the cabin that would cover 90% of our need but with grid and generator as needed for outage or peak usage. I've also played around with micro wind and built a 3 ah windmill from a converted ceiling fan. Used PVC pipe to cut the blades. A fun waste of time.

|

|

gcrank1

Member

|

# Posted: 7 Dec 2025 07:48pm - Edited by: gcrank1

Reply

The shack had a 600w (6 panels and not the cheapies) thru a 50a SCC to 6 huge 120ah Lead Acid bats wired Wrong; ie, the SCC into the parallel wired bats on one end and the output to the 1KW PSW inverter out the other..... I revamped all that in the early years (3 times?) until the last LA bat died then agonized over buying new LA golf cart bats or changing to LFP.

Opted for LFP and haven't looked back

But about that time we tore down the solar array (2022?) and it hasn't gone back up, nor am I inclined to. Here's why, our elec needs are minimal, our LED lights are mostly self contained USB rechargeable (can hang em anywhere w/o wiring!), no energy hog fridge, etc, the nuker runs on the little 2kw psw gen when needed (not much) so the only hardwire is 2 small ceiling fans c/w LED lights. I power them off the 100ah LFP bat (have 2) that I swap out as needed to recharge at home thru a 300w psw inverter. If I want to run the toaster I swap in the 750w msw inverter (toasters dont care), that's a quick run.

So, all that to say that the LFP bats are light and easy enough to swap and haul and they fully charge at home within ~2.5hrs off my power supply. If we had grid Id just set up charging for emergency outage (rare here) at the cabin with the gen and charger for long grid down (kinda like a small scale 'powerwall')

My array and all are in the toolshed awaiting a change of heart, lol. But I do have a 200w small portable pwm system that I could haul out anytime.

|

|

philpom

Member

|

# Posted: 8 Dec 2025 08:01pm - Edited by: philpom

Reply

For a number of years we cooked many of our winter time meals on the old boxwood stove. A few years back we replaced the old stove with an efficient model that can burn through the night. A Godsend for me!

We enjoy winters the most although it's the most work. Pictures at 2019 except the obvious one of the new stove, lots of work done since 2019.

I'll edit thos post and note that I have issue withe photos no uploading and when they do many times they are cut off....

20191128_125001.jpg

|

20251122_205204.jpg

|  |  |

|

|

philpom

Member

|

# Posted: 8 Dec 2025 10:12pm

Reply

By 2020 we had ramped up our work on the inside, we started finishing out the upstairs and downstairs. Trim, paint, framed in the bathroom, and installed the kitchen counters, and flooring. It started to look cozy and the wife's joy grew.

Cabinets were pre-made from Lowes, while I framed in the bathroom, the shower pan was an Amazon special. It was hard to find one the right size. I ultimately installed a propane instant hot water heater for it and that introduced the world of city showers. Prior we had used every method known to man including early on a water bottle with a knife whole in the lid. The best alternative was a "Hudson" sprayer I fitted with a Schrader valve and 12v air pump. Fill that with warm water and it gave a pretty good shower, we did that for years. Of course the RV water pump and instant hot water in a real shower blows that away but if you are pondering a cheap off grid option, the sprayer is golden.

20201123_103215.jpg

|

20200907_112718.jpg

|

20200907_112819.jpg

|

20210705_143543.jpg

|

|

|

philpom

Member

|

# Posted: 8 Dec 2025 10:19pm

Reply

More bathroom pics.

20210709_165015.jpg

|

20210709_165031.jpg

|  |  |

|

|

|