| . 1 . 2 . >> |

| Author |

Message |

deafdrummer

Member

|

# Posted: 2 Nov 2015 11:29am

Reply

Hello everyone,

I've been reading through here for the past week. I would have put off posting my intro had I found postings with building comparisons (comparing Derksen with Cook, Leland, and Graceland buildings). I'm having to decide which building I want to go with, assuming that I live in southeast Texas to near central Texas. I did take a look at HD and Lowes buildings, but that was last year, and I don't remember what it was I didn't like about them (lack of cabin style options?).

Currently, I've been living on the road for over two years, and I finally got a travel trailer that I live in (for 17 months so far). I'm not worried about "downsizing," as I would be upsizing because my travel trailer is 7.5X12 in the body and has EVERYTHING except laundry and dishwasher. I'm thinking of going to a size of 10X16 (internal) with lofts with the aformentioned brands of my choice. I know that my TT is not a long term solution and need to move out of it and sell it before I end up sending it to the landfill (sidewall delamination has started in spite of my efforts to prevent it).

My situation is that my TT (travel trailer) is fully docked (power, water, and sewage) on a friend's property, and we're on real good terms. I have expressed an interest in having a portable cabin brought out here and finished out, which my friends have approved. That way, when I have to move, I can just arrange for the driver to pick it up and move it to the next location.

I know nothing about the shed business, as I have never even owned a house in my life. I've lived in apartments, rented houses, and another travel trailer 20 years ago. I realize there's a lot to learn about having a cabin, even as small and portable it is. I have to keep money in consideration, as I'm struggling as a writer right now, though I have savings to drop on a building on the spot if the situation warrants it (my furnace is out, water heater is malfunctioning, and worse, I have two roof leaks I haven't been able to fix in spite of sealing up the roof up there THREE TIMES).

I have gone out to see several of the brands of pre-fabbed buildings, so I have an idea of their construction methods visually, as well as how the different sizes feel, both utility and lofted barn style, though I want the lofted barn style (I'm not quite 50 and still in very good shape) either for storage on both loft ends or storage on one loft end and combined storage/bedding on the other loft end with a divider wall.

I have to wonder about the need for soffits and ridge vents for a lofted barn style with cathedral ceilings instead of an attic. I did read the thing about "10 things not to do in building a cabin in the south," but I have to be careful because the author mixes in north-south politics, which is not appropriate for this topic. A ridge vent is a ridge vent, regardless of who builds it. I wonder about the gable vents on Derksen buildings, and whether they are sufficient/proper for the climate in south east Texas as well as, say around College Station.

I have to go pre-fabbed because I don't have the tools to build a cabin from scratch. I'd rather have a shell I can finish out largely by myself (no sheet rock, but tongue and groove horizontal pine paneling throughout except for flooring, which I haven't decided on).

I like the postings on projects I have seen so far, and it seems that Derksen buildings are far more common in this forum than the other brands. What I am looking for is a brand-by-brand comparison, history of usage, and which is appropriate for the kind of weather we have here in southeast and central Texas.

Thank you,

Stephanie

|

|

MtnDon

Member

|

# Posted: 2 Nov 2015 12:05pm

Reply

Question... Do you want a well insulated roof? The recommended minimum for SE TX, climate zone 2, is R-30. That is impossible to achieve with an off the shelf shed.

|

|

deafdrummer

Member

|

# Posted: 2 Nov 2015 12:32pm

Reply

Yes, I do, mainly for heat retention during the winter. I tend to run cooler than most people (72-75 on the thermostat freezes me out, so I prefer 78-80).

What is your suggestion on the roof situation? Build a strip extension on the inside side of the rafters? (picture your gambrel rafters with 2X2 or something attached to it end-on-end, extending the depth of the space within ceiling-to-roof)

|

|

creeky

Member

|

# Posted: 2 Nov 2015 01:58pm

Reply

I would look at the "perfect wall." and the Texas cool roof. you outsulate as opposed to insulate.

having done it. it is faster and easier to build than an insulate wall. and it is warmer and helps with humidity.

ChuckDynasty posted a video of a guy who did a perfect wall build in Texas. I built a perfect wall 10x14 cabin that turned out real well. You can find my build creeky's chalet. sometink like that.

And I posted a link to the perfect wall specifically referencing texas/southern US. might want to have a look.

|

|

MtnDon

Member

|

# Posted: 2 Nov 2015 01:59pm

Reply

Check with the potential builder, ask if they can frame the roof with at least 2x6's and then spray closed cell foam on the underside and completely fill the rafter bays. That would get R30 with closed cell foam. 2x8's or 2x10's would be even better as closed cell foam cures hard and is usually installed short of the maximum rafter depth as if it protrudes beyond the lumber it has to be cut off.

An alternate would be to install sheet foam insulation on top of the standard OSB roof sheathing. With XPS you would need about 6 inches. If polyiso that would be about 4.5 to 5 inches. There are then different ways to finish the roof with the final roofing, shingles or metal.

Both of those methods avoid the roof venting issue. It can be done but not without proper design.

The guy that authored that "10 things not to do...." article is an expert in the field. Google Building Science. Lots of articles there on insulation and unvented roofs.

|

|

deafdrummer

Member

|

# Posted: 2 Nov 2015 03:16pm

Reply

Creeky, let me see if I understand this correctly.

First thing is, you have your house framing, then on the external side of the walls, you put up your plywood, then house wrap on the plywood, then insulation sheath onto the house wrap, then the wooden straps that go across most of your cabin horizontally, and then attach the siding to the straps? I'm trying to get the terminology right.

As far as the roof goes, I'm looking at the Texas cool roof with batten-counter-batten under a metal roof. I'm waiting to hear back from the prospective cabin lot to see if they can do 2X6-8 rafters. I need to find out if they can do the cabin without siding, just the framing. All of the brands of buildings I have looked at do not come with house wrap at all. It is a single-layer siding, such that when you're inside, you're really looking at the back side of the external siding.

|

|

creeky

Member

|

# Posted: 2 Nov 2015 06:17pm - Edited by: creeky

Reply

You got it. It's really pretty easy to do. It is a bit of a fright when you see the cost of the 6 and 8" screws. But in the big scheme of things. For a little building that you want air tight and insulated to save on heat/cool costs. Very cost effective. I'm finished now at around 3,500 including everything. for 140 sq ft of super comfortable. I'm jiggy with dat.

Plus. I used mostly 1x12" pine for the wall/roof cladding (plywood on the two opposite corners for shear bracing). and the look comes out real cottage country inside. everyone who has seen it likes it. which. i guess is a good thing.

I watched kijiji (canada's craigslist) obsessively for two years to get all my polyiso. So the cost was far less than spray foam inside the house. And no labour cost. With a result that last winter, the coldest in 44 years, i heated easily with an 8k btu heater. which, if you knew about Canadian winters, is the equivalent of cooling your texas house with a case of cold beer. Or your lover's shoulder after you forget a birthday party.

ya that batten / counter batten is the latest way I've seen to do texas cool roof too. for a simpler method see my "shizzer shack" build. Basically I just strapped it one way and put the tin on. It's 4 summers now. I checked this summer and I see no change in the battens. My neck of the woods is pretty humid in the summer. But if they've gone to double battens in your area ... probably for a reason.

The article I put up "10 things not to do..." is by a Canadian Joseph Lstiburek. the guys a frickin' genius. and what I like, aside from his dry sense of humour, is that as the years have gone by he's not been afraid to say he made a mistake. which. hey ...

|

|

deafdrummer

Member

|

# Posted: 2 Nov 2015 07:16pm - Edited by: deafdrummer

Reply

The issue with doing the cool roof and the perfect walls is that Derksen doesn't ship a building without siding nor metal/shingle roofing. I'd hate to have to take it apart in order to build this kind of roof.

I have to ask - is it REALLY necessary to do these structural changes? I have a full-size roof AC unit, and it just freezes me out even in the hottest of days. Surely, an appropriately-sized AC would take care of the cooling/heating needs...

|

|

|

MtnDon

Member

|

# Posted: 2 Nov 2015 07:52pm

Reply

A shed is not designed to be a house; it is a shed, some fancier than others. Some shortcomings should come as no surprise. Are the suggested changes necessary? If minimizing energy use is an important goal, yes. It will be difficult if not impossible to economically introduce high level insulation into the structure of the typical shed. That can be less important for sheds that become part time recreational cabins. However my opinion is that good levels of insulation are very important when the structure is to be used as a full time residence.

Nothing has been said for far in this discussion about what rules, permits and inspections will need to be followed. Enforcement of the various codes varies between locations. Many standards may be difficult to meet with a shed based building. If you have a location in mind it would be wise to check with the building department before spending any money.

|

|

deafdrummer

Member

|

# Posted: 2 Nov 2015 08:30pm

Reply

This isn't a normal shed, but specifically the Loft Barn Cabin from Derksen. Are you saying that's not even meant to be stayed in, period?

|

|

MtnDon

Member

|

# Posted: 2 Nov 2015 09:32pm

Reply

To me it is still a shed, albeit a good looking one.

The suburban area I live in will not permit one of these to be used as a residence. That is not without the foundation, walls, floor and ceiling / roof meeting the same standards required of a conventional home. Out in the boonies of the county they are more lax but they still require insulation standards to be met.

The walls are sheathed with a single layer of sheet siding. No housewrap or building felt as a water, water vapor or air infiltration barrier. Half the insulation battle is won with well executed housewrap / building felt. A "normal" residential wall is sheathed with OSB panels, then housewrapped and then the finish siding. The OSB sheathing provides structural rigidity. The housewrap the barrier to air movement and as a water control layer. The final siding is mainly cosmetic. In a typical single layer shed wall structural strength is reduced if/when the siding panel deteriorates, is damaged. In a typical close to the ground shed the lower edge of the sidewalls are subject to a lot of splash back when it rains. Eventually problems can develop. Then that is a pain to repair well.

The basic roof design is not easy to insulate well with any degree of ease, or dismantling and rebuilding. Doubly so when most users of the building type want to make use of the space provided by the gambrel roof.

IMO, and it is just my opinion, the money would be better spent on a small modular home or what is known as a Park Model. YMMV.

|

|

deafdrummer

Member

|

# Posted: 2 Nov 2015 10:00pm

Reply

I have to agree that sheds aren't quite how I want them to be, HOWEVER, I do have to have something to live in, before my TT becomes unlivable. So, a park model is the way to go? But first, I have to do something about my job situation. I will not move back into the city and restart the process of throwing away money at apartments. Not sure what to do... I have tried to find online resources for converting a travel trailer to a tiny house (yes, the sidewalls and roof has to go, but what to replace them with and make a sturdier house inside without increasing the weight too much?).

Now, I will have to look around for the park models and find something I can afford, as I don't want to go too big. I don't want too much house to clean, either.

|

|

deafdrummer

Member

|

# Posted: 10 Nov 2015 08:23pm

Reply

That did not work out, either. The park model, the TT strip down, and possibly the cargo trailer idea is out, too. It looks like I'm down to the idea of the cabin. I went up to the Derksen factory an hour from here today after my salesman had to close shop temporarily for a family emergency (I wish him well).

I did find that they can do a lot of things if you're willing to pay for them, including:

2X6 construction in the roof and walls (they will even do 2X8, but it is very expensive and very heavy for the mules and trucks)

SmartSide SilverTech siding

electrical wiring

foam insulation in the rafters and walls

build with 8ft walls instead of the standard 6.5ft walls

I will have them put a metal roof on it with a stock color and have them use a specific color on the outer walls from a paint code I have.

|

|

Steve_S

Member

|

# Posted: 10 Nov 2015 10:04pm

Reply

There's a thread on here with an almost identical cabin by RifRaf

here's the link: My cabin shell (shed)

I think you'll find that it can get very expensive, very quickly having someone else do a lot of work for you.

The std 2x4, 24 on centre walls are the typical they offer. 2x6, 24oc with 8' walls certainly better and same with the rafters.

To keep it movable on a truck / trailer or... there's height restrictions and obviously weight & practicality. Some type of cross bracing or metal strapping running diagonal corner to corner between the studs & sheathing for shearing. It just makes it stronger. This is what you'll see in high wind areas and quake zones.

On weight, the lightest insulation I can think of is ISO Foam Board. It's R6 per inch and the foil faced is excellent as a layer between the exterior wall & siding, also for a roof with airspace between. It's not cheap in the retail world though. Check with commercial roofing companies, the guys who do schools, stores, malls, not residential as far as I know. Around here they use ISO a lot but not the foil faced stuff, the treated paper faced.

One thing about foams... I can't say for the spray stuff that fills a wall cavity, though. Is that XPS or EPS Foam if fitted tight between the studs becomes a strong structural component. XPS is very dense and fairly light considering. Mice & critters generally won't bother foams and won't live in it, as a BIG bonus

.

Wiring would be minimal, 3 lights (bath main, loft), 4 switches (kit, bath, main, loft) maybe 4-5 plugs. 12 devices, max 1 circuit... use 2, 3 circuits so you can add more later if needed. Small breaker box, 45A with 3-15A breakers would likely do.

I'd suggest a light coloured Tin Siding on top of OSB Sheathing to reflect the heat away and give best wet protection. Lighter the roof colour the cooler it is too. LOL.

If memory serves, A Tiny house can be a max of 8'6" wide x 14'6" high from road surface and 24' long depending on trailer class etc. 10,000 Lbs isn't hard to hit ! once you got stuff in there.

So are you going to leave it at that property ?

Maybe move it later to another property by transport ?

Try to build on a trailer big enough & strong enough ?

Sorry if this is long, but I seriously got into thinking on Tiny Houses and such and was even going to build a survival one on an old 21 foot RV but things change in life and new turns around every corner.

Take the budget you have in mind and double it ! Then hope for the best... it's never the big ticket item that get's ya, it's the pesky little expenses that get ya... Death from a thousand stings, or something like that LOL

|

|

Julie2Oregon

Member

|

# Posted: 10 Nov 2015 10:42pm

Reply

I live in Texas currently. The thing that stinks here from what I can tell SO FAR is that all of the sheds you see for sale are done by national companies so they're bog standard. Different story where I'm going in Oregon. There are shed builders that are local businesses run by licensed contractors. Sheds, small barns and chicken coups are their bread and butter but they can build anything you want, the way you want it, and are increasingly doing cabins and small houses because the demand is there. And because they already have the warehouse space, tools, materials, and personnel, they're able to do custom work at a dang good price.

This is what I'm doing. The guys who are going to build my cabin on my land are shed builders. But they're building what I want and building it according to code. They'll have all of the components done and ready to go, bring everything to my land and put together in a couple of days on my foundation. Simple.

Look around and ask around. Maybe you can find similar local shed builders in Texas. They don't exist where I live in West Texas but that doesn't mean they don't exist at all.

|

|

deafdrummer

Member

|

# Posted: 10 Nov 2015 10:47pm

Reply

That's why you have to spread the stings out, so it doesn't kill you. This is how the rest of the world does it; one stick or brick at a time, as credit doesn't exist in those parts.

I went broke in 2000, and I had to start ALL OVER AGAIN. Everything I had left over fit in the back of my stepmother's car. I even lost my car I had at the time. I've been fighting for the past 15 years to get back on my feet. Meanwhile, I had to piece back together my life. One month, I'd buy new shoes for work, the next month, I got a heavier coat to stay warm, the next month, I bought some pans, then some dishes so I would have something to eat out of. I was able to buy another car shortly before I moved to Houston.

A few years later, I was able to buy instruments on a cash basis, still one piece at a time sometimes, and play again. Things changed again two and a half years ago when I was forced out of the retail company I worked for because they were cutting costs (I had been there 8 years, and they kept giving me raises) and hiring new people at nearly 50% lower than my rate. Now, I'm having to start over. Again... This time, I had savings AND I cashed out my meager 401K, which I definitely needed and still have a little bit left over. I didn't have to lose anything this time. I moved out of Houston to go on the road and worked at renaissance faires, traveling around the eastern half of Texas until it became clear that I was not going to get the good jobs for lack of connections and a general failure to accept that I could do a good job in spite of being new and being deaf. My last job was rough... As soon as I finished that (I was a dishwasher at one of the faires in April/May, and I was the ONLY ONE to make it through the entire show, and I'LL NEVER DO IT AGAIN), I high-tailed it out of the area and came down to the Cleveland area, an offer that was extended to me around mid-March.

Now, I have been told by my hosts that they really like me here because I can handle being by myself much of the time and make the effort to help with mowing 2-3 acres and general upkeep on the place, not to mention I am armed and ready to protect my friends if need be.

Yes, I did read RifRaf's thread from beginning to end before I even signed up here.

Thanks for the idea of using TIGHT FITTING foam sheets. I noted that in my notes. That way, it'll stay in place up in the rafters until I can lay up paneling. I also went to different lots on the way to Conroe last week and saw a few buildings with electrical roughed in, and I saw how it was done. This can be easier to do with foam sheets. Just position the foam pieces before/during/after running the wiring in, and then spray some canned foam around the wiring gaps.

This will not be a tiny house on wheels. It'll be loaded on a flat bed, and dropped off and leveled on concrete blocks with the help of a mule. Out here is sandy soil, not muddy, especially where I am to put the house. There is a possibility that this house will get moved again one more time after the initial drop, but I'm on such good terms that I can be here indefinitely if I want to. They're getting older, and they're not going to be able to keep up on the land maintenance (he does not mow, period, and she cannot do it anymore).

I just need to find a job locally where I can make decent money and use that to get rid of these bills and start settling down. It's really nice out here with lots of trees, more than I've seen in Houston.

On my way back from Corrigan, I stopped at a Lowes and picked up the paint card with the color I wanted so I can relay that to the builder at the time of purchase.

Sorry for the long post.

|

|

deafdrummer

Member

|

# Posted: 10 Nov 2015 10:56pm

Reply

I did mention I went to the factory where they build the buildings. As I mentioned also, they will build it pretty much how you want it. They can even insulate the floor if you tell them ahead of time.

|

|

Julie2Oregon

Member

|

# Posted: 10 Nov 2015 11:05pm

Reply

Factories have basic floor plans and stock sizes and materials. They can only change up some things. A small business can build EXACTLY what you want, any size.

Short of that, maybe you can barter skills and have someone teach you to build what you want? Places like Habitat for Humanity ReStores and salvage yards can provide materials for cheap.

|

|

Steve_S

Member

|

# Posted: 11 Nov 2015 07:29am

Reply

Absolutely have the floor well insulated ! It's not something you want to do in retrofit mode... Ohhh that would only lead to a LOT of Drunken Sailor Talk !

Wiring can be Surface Mounted with Armoured Cable... More expensive and not so pretty BUT you can go pseudo Steam-Punk-ish & use it (can get lots from commercial building demolition, cheap). You can also lay it up and put conduit over it... Cost of armoured 14/2 here (retail 0.89 per foot)

Note: In my own place which I am building now, there will be no wire inside ANY Exterior wall, all surface mounted and covered in wood raceway channels. (walls are to be finished inside with wood as well, so it will blend in naturally).

TWO Books I STRONGLY RECOMMEND: DEWALT® Carpentry and Framing Complete Handbook and The Visual Handbook of Building and Remodeling, 3rd Edition There are many electrical books out there, the DeWalt one is pretty good, as I'm Canadian and stick closely to our specs I use other reference materials...

Do keep in mind for the future... When this is built & on the property it will weigh too much to be moved again. These buildings by their design are intended to be dropped on location and not moved again, they are not designed for long term survival (of the building), essentially disposable.

Therefore critical things to do, ground prep with really solid base, excellent drainage away from the building, gutters to move rain away... Tin siding is best as water run off from roof (lack of eaves etc) will cause a lot of troubles later...

The Foam can be used in walls, roof, under floor. Finding it cheap isn't easy but doable. Retail stuff usually doesn't go thicker than 2" but I've gotten commercial stuff 2-1/2", 3-1/2" 4.0" and even 5.1/2". XPS Foam is R5 per inch and ISO R5-R7 pending on facings. A good reference @ Canada Mortgage and Housing Corporation, Insulating Your House

Cleveland can get mighty chilly so there's no substitute for thinking about staying warm in winter and cooler in summer (keeping heat out).

|

|

deafdrummer

Member

|

# Posted: 11 Nov 2015 10:26am

Reply

Thanks, Steve_S. I'm referring to Cleveland, TX, not in Ohio. You couldn't pay me to live that far north by the Great Lakes. I have been to Sandusky, 30 miles to the west of Cleveland, OH, so I know it can get chilly even during the summer. I don't know how often it would even get above 75 up there.

Also, a finished-out 10X16 can't possibly weigh more than say, a 16X32 if you load up a moving truck with everything from the cabin and move the stuff on the day the cabin gets moved again. It won't have a full-size residential stove (table-top stove and table-top oven - my friend Betty has both) or fridge, and no heavy bed frame in it. Everything is to be minimal, no grandpa furniture or anything requiring two big men to move out. That way, I can move everything out of the cabin myself while waiting for the driver to arrive. I have moved beyond the materialist stage and want to stay simplified (I already do in my 7.5X13 travel trailer).

I will think about the suggestions regarding gutters, or I could do angled blocks on the ground along the perimeter of the house so that run-off will hit the blocks before hitting the ground and not splash it onto the walls. Gutters are a PITA to clean out.

|

|

Julie2Oregon

Member

|

# Posted: 11 Nov 2015 06:28pm

Reply

Steve_S

Having the wiring outside the interior walls intrigues me. It would enable my cabin to be further along and inspected so we can deal with the electrics another time. Does the schema you describe meet current building code and is it a lot more expensive to do? If I was careful about where I located the panel, I probably wouldn't need to run more than 30 feet of wire. I'm just looking at kitchen and bathroom, which are going side by side and will share two walls, and a bit of the living room.

|

|

skootamattaschmidty

Member

|

# Posted: 11 Nov 2015 06:47pm

Reply

Off topic but cheeky I love your analogy of the cold shoulder after forgetting a birthday!

|

|

Steve_S

Member

|

# Posted: 11 Nov 2015 08:48pm - Edited by: Steve_S

Reply

@ Julie:

Using Armoured Cable satisfies building electrical codes in most areas. The general reasoning for not allowing non-armoured wiring is that it's susceptible to damage and can be very easily damaged. The armour is pretty darn tough stuff, hence why all commercial facilities from industrial to office complexes use it. It's also a flexible conduit which has the added feature of "containment" should something go awry.

This is NOT wired like conventional wire... it has to be cut back properly, use insert sleeves between the wire and armour where cut back to go into boxes (for plugs & switches) and uses slightly different connectors to the boxes for the wire. It must still be attached to the walls per code or run through chases. The attachment is via round clips as opposed to wire staples.

Costs: Well it is of course more expensive than conventional PVC encased wire (metal costs more)...

but some parts are cheaper as there needs to be less materials.

HomeDepot.com USA:

100 ft. 14/2-Gauge Solid Metal-Clad Cable @ $34.99 /each

VS

Romex SIMpull 100 ft. 14/2 NM-B Wire - White @ 24.77

1-Gang Electrical Utility Box (for armoured cable) @ 2.10

VS

1-Gang Electrical Switch Box - Silver for PVC coated wire @ 2.44

NOTES:

Kitchen Plugs should always be on separate breakers. Either Split Plug 15a (means 2 breakers per plug, with common Negative requires 14/3 wire. OR Single 20A Plug with one breaker per plug requiring 12/2 wire.

Bathroom MUST be CGFI to prevent electrocution, is ideally 2 circuits (1 lights, fan etc, 1 plug) most often it's one circuit with the CFGI Plug as the first point and then after than everything is protected by that CGFI Plug. You could also use a CFGI Breaker in the panel but they are more $

The Armoured wiring can be painted to hide it, or highlight it, even splash clear on it to keep it shiny if ya want... leave it "natural" & it will slowly tarnish & lose the luster.

Next time your in a Big Box store or something industrial/commercial just look at the armoured wiring and the boxes, cover plates etc that are used.... It can be pretty spiffy if you think about how to apply that to a small home. Something to be said about Steam-punking it in... Gee, if only Armoured cable was available in a copper or brass colour....

@deafdrummer

Gutters: You can easily use Foam Gutter Guards which keep junk out and let water in & through. Low Maintenance for gutter care... unless you like playing in gutters... LOL Wink Wink Nudge Nudge... That would allow you to save your rainwater and put it to good uses. Rainwater is a valuable resource, don't waste it.

|

|

deafdrummer

Member

|

# Posted: 11 Nov 2015 09:08pm

Reply

You already lost me on the electrical wiring. I better get the electrical package with the cabin and be done with it.

|

|

deafdrummer

Member

|

# Posted: 12 Dec 2015 08:08pm

Reply

Well, I lost my fridge in the RV, and now I have to use my next-door neighbor's fridge. The way I want the cabin built is forcing me to do the electrical rough-in, as they would have to build walls to complete the wiring.

I'm debating ordering the cabin no later than March 1. I may have to do it much sooner than that. My question is to figure out how to make the cabin useful as fast as possible, without building myself into a corner where I have to tear everything out in order to finish out properly.

My guess is, I need to run wiring only for what I need (bathroom switch and light, and kitchen light and outlets) and the plumbing, and then insulate the exterior walls for the bathroom and kitchen only and panel that part of the house, and put the flooring down for the bathroom and kitchen first. That way, I can cook, eat, and shower in an emergency while I make money to pay down the cost of the cabin and buy building supplies as budget allows. My travel trailer will become unlivable fairly shortly, I think.

|

|

deafdrummer

Member

|

# Posted: 24 Dec 2015 04:22pm - Edited by: deafdrummer

Reply

I am to order my cabin after January 10th! It'll be a Derksen lofted barn cabin, 10X16 with no porch, 2X6 construction, SmartSide SilverTech, 4 insulated windows, 3/4 decking for the floor, custome paint with a specific paint code and white trimming. I need to see about a screen door and whether the windows have screens on them.

I am ready to do this, but am giving myself time to learn construction techniques like roughing in wiring and plumbing, measuring out for a bathroom, etc.

I'm wondering whether to go with 12-ga romex or 14ga romex for the interior wiring to outlets, switches/dimmers, and fixtures in a cainb this size.

|

|

Mzmizery

Member

|

# Posted: 27 Jan 2016 12:38pm

Reply

I see many going with Derkskin buildings, but I'm not sure why. Graceland buildings have a roof ventilation system included. I recently had a Graceland building built onsite. It's a 16x32. It has the ventilation in the roof hurricane straps on roof and floor. 16" centers they raised our gambrel roof so we have a standing height. We opted to add the radiant barrier in the roof and the builder put the house wrap we purchased around the building at no charge. The ONLY thing I don't like is they no longer do 2x6 in the roof gables, but we will add some egg carton or some panels before insulating. We live in a warmer climate, but not as hot as Texas. Our land is in the county so there are no codes or inspections, although we do plan following basic code. Park models are way too expensive especially for their size. This is the most effective and affordable way to get debt free. We will soon be starting the inside and pay as we go....

|

|

deafdrummer

Member

|

# Posted: 27 Jan 2016 08:34pm

Reply

Derksen does have a ridgeline vent, too.

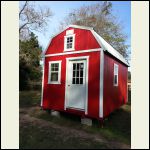

I got the cabin today per the specs:

8-ft walls

Smartside Silverside painted SW Show Stopper Red

Metal Roof painted Alamo White

2X6 construction throughout

3 insulated windows and one extra window for the loft area

Insulated floor

3/4" decking for floor (turned out to be 1.5")

No porch

Custom location of the windows and front door

|

|

deafdrummer

Member

|

# Posted: 27 Jan 2016 09:53pm

Reply

Here it is!

cabin001.jpg

|

cabin004.jpg

|

cabin010.jpg

|

cabin013.jpg

|

|

|

deafdrummer

Member

|

# Posted: 27 Jan 2016 09:55pm

Reply

And the interior.

cabin017.jpg

|

cabin018.jpg

|

cabin019.jpg

|  |

|

|

| . 1 . 2 . >> |