| << . 1 . 2 . 3 . |

| Author |

Message |

Brettny

Member

|

# Posted: 9 Jan 2026 05:38am

Reply

14x18 will be bigger than you think if your sleeping in a loft. Our temporary cabin was 10x14. We had a propane stove, fridge, bunk bed, countertop and wood stove in it. Yes it was tight but fit 3 adults durring hunting season.

I would get rid of that middle beam. 14' I believe is really on the edge of needing it and just that one beam adds alot more labor and expense. If you must keep it theres really not much holding you back from going 16' wide and really needing it. Your going to have a easier time finding 16' lumber also.

|

|

DRP

Member

|

# Posted: 9 Jan 2026 07:55am

Reply

Use the span tables rather than guessing. 2x12's are used for 16' spans. With floor trusses and I joists I've gone up to 24' spans with no center girder.

I suspect this is not congruent to the triangle.

Correct, I'd hang the rafters from a ridgebeam.

R802.3 Ridge.

A ridge board used to connect opposing rafters shall be not less than 1 inch (25 mm) nominal thickness and not less in depth than the cut end of the rafter. Where ceiling joist or rafter ties do not provide continuous ties across the structure, a ridge beam shall be provided and supported on each end by a wall or girder.

aside; This is a footnote from the rafter span tables in chapter 8 (that's the roof framing chapter)

.The tabulated rafter spans assume that ceiling joists are located at the bottom of the attic space or that some other method of resisting the outward push of the rafters on the bearing walls, such as rafter ties, is provided at that location. Where ceiling joists or rafter ties are located higher in the attic space, the rafter spans shall be multiplied by the adjustment factors in Table R802.4.1(9).

With 2x6 walls I would notch in a 2x6 ribbon for the loft joists and avoid all those jacks. Look at the right side 2nd floor joist support in the fig below. That is a holdover from balloon framing, with 2x6 walls I let in a 2x6... Do fireblock each stud bay between floors, the downfall of balloon framing was fire could race up those tall hollow walls... thus the call for blocking at each floor.

BTW, going back to the original floor ideas, some background knowledge might be in order. When looking at 2x4's and 2x6's notice that the 8' and 9'er's are often stamped "stud". They are graded as a column not a bending member. Never lay a stud down. It is a #3 with #1 edges... not worth a damn as a beam or joist but has enough edges to catch sheet goods.

|

|

DRP

Member

|

# Posted: 9 Jan 2026 08:07am

Reply

Another thought depending on access at this spot.

If you can get trusses and a boom truck in, "room in the attic" trusses can create a good loft space fast.

When in doubt I get them to come look at access, alot of what I read is city people saying "the truck can't get there" when all they really know is their fiesta can't get there. Our operators like a job they can brag about  . .

|

|

TNwoodsman

Member

|

# Posted: 9 Jan 2026 11:43am

Reply

Thank you DRP for your wealth of knowledge.

One upside to this particular site is that it is accessible.

|

|

DRP

Member

|

# Posted: 9 Jan 2026 04:40pm - Edited by: DRP

Reply

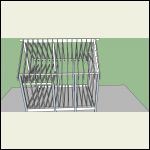

Another way to get more room upstairs is to have trusses incorporate a porch roof, then the rafters are springing from the wider edge of the porch rather than from the building line. Below are a couple of pics from an attic truss job. Notice they did a sidewall in the lower set to give us a room inside.

attictruss.jpg

|

atttruss.jpg

|  |  |

|

|

DRP

Member

|

# Posted: 9 Jan 2026 10:41pm

Reply

As you think about that 1st building.

In that same "neighborhood"... in the same part of way back of beyond, was another job. Cool neighborhood, about 500 acres inside the national forest that a group of friends bought when the ornery old timer died.

It's all just thinking stage right now, rather than being beat up you are being exposed to ideas.

This was a cool job. The garage with MIL suite above was what we built first, attic trusses are laying in the driveway.. toy parking/shop below, apartment above. The dog in the driveway was one of the best we've ever had. Mrs client lived there as soon as we could get her in, for the duration of the main build. 2nd shot you can see the shed dormer in the MIL/garage, there was a matching shed dormer on the other side of the ridge, we are starting to lift the timberframe main house in the background.

As time went on, we took care of my MIL here and they took care of his MIL there, she never lived in the MIL suite, preferring full service in the main house  During the main house construction I had a shop set up in the garage where we milled timber and trim, finished and parked their stuff in secure storage. Friends, family, a caretaker have all lived in the MIL apt. During the main house construction I had a shop set up in the garage where we milled timber and trim, finished and parked their stuff in secure storage. Friends, family, a caretaker have all lived in the MIL apt.

If it is going to be multigenrational, think about getting the scale right. Do, but plan. I've worked for the 7th generation, the thinking is different.

|

|

TNwoodsman

Member

|

# Posted: 10 Jan 2026 09:57am

Reply

Thats awesome DRP.

I love the sound of that.

When I build on a bigger scale, I definitely have my future generations in mind since I have 4 young boys.

I have 42 acres of predominant pasture land that was prior used as a horse farm and the fields were cut for hay.

Its very rolling.

I am currently planning and looking at buying trees to build character for the future generations to enjoy....red oaks, white oaks, sycamore trees etc. Giant trees that will be here long after im gone; their branches for climbing and tree swings and their canopy for shade.

I still haven't committed in my mind about how im going to build the loft. When I change ideas and approach, I have to learn and research how to do it since its all new to me as a trade and as a skill....as a science.

More later. Going on a walk with the family.

|

|

DRP

Member

|

# Posted: 10 Jan 2026 10:25am

Reply

The 2nd build typically happens when you are empty nesters, life gets busy for the next 20 years or so.. Don't build the 1st building too small and think about what it will become through time.

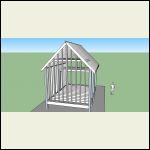

Below is a sketch just to show what springing the roof from a wider stance would do to the room upstairs. I included vertical struts at 5' tall which is typical in an attic truss and the ceiling joist web member is 85" above the bottom chord, it is a little over 6' wide at 7' high and the room is 10'6" wide overall.

|

|

|

TNwoodsman

Member

|

# Posted: 10 Jan 2026 01:32pm

Reply

DRP,

If I rest the loft floor joists on top of the exterior wall double top plates, the joists will still have a girder that they attach to on both ends, just like framing the foundation floor, correct?

And then I could use a ridge board (and not beam) and the ridge rafters would then rest on the second floor girders via the seat cut and birdsmouth. This forms the triangle.

If this is true, you have told me I can use 2x8 for the floor joists so then I presume my loft floor joist girders will be 2x8?

1 girder? 2 girders?

I am trying to consider all the way I can do this and weighing the pros and cons.

IF I use a ridgebeam and I place my loft floor lower to gain more headroom in the loft, you have called for a double LVL beam. To clarify, when you say double, you mean 2x 1.75" x 11 7/8 thick beams 20 feet long (allowing for overhang)? I ask this because I have seen varying thickness on LVL beams. I have no experience with LVL. Never shopped for or seen them.

The ridgebeam needs support on both ends. What does that support look like? I know you said ideally it is supported by a post that runs straight to the ground. But...if the beams are 3.5" in width, can I use 2 2x6 that span from the ridge beam to the double top plate? If so, would it do me any good to frame 2 2x6 directly below the top plate that runs to the bottom plate? Essential a column of 2x6s that spans from the bottom plate to the first top plate and then continues from the second top plate to the ridge beam? I kind of feel like that makes sense but then I think you are going to say that I follow the travel of the load on the ridge beam that it will travel down the 2 2x6 sitting on the top plate and run along the top plate instead of being transferred down because the top plates break the continuity of the column.

Ok. Long post. Sorry. Thank you for your time and energy as I continue to learn.

|

|

TNwoodsman

Member

|

# Posted: 10 Jan 2026 02:20pm

Reply

DRP,

One more thought/question.

If I use a ridge BOARD but I place the loft floor lower and do not tie in the rafter joists to the loft floor, I can get away with using a ridge BOARD IF I use rafter ties? The ones that go on the lower third? This framing method completes the triangle however the rafter ties then take up headroom making the loft not very functional as it was intended.

The million dollar question.....what if I only used rafter ties outside of the loft area...so the loft is 14 feet wide, 8 feet long. I could put a rafter tie on the end rafter in the loft and then every rafter past the loft gets a rafter tie. What does that look like structurally?

|

|

Brettny

Member

|

# Posted: 11 Jan 2026 06:56am

Reply

You could also do a gambrel roof to gain head room. Blocklayer.com has a prety good gambrel roof calculator that when you subtract the floor joist will give you head room.

|

|

DRP

Member

|

# Posted: 11 Jan 2026 08:47am - Edited by: DRP

Reply

A ridgebeam over just the loft would need to support 7' of roof width x 8' of ridge length x 30 psf=1680lbs.

A column at each end of that loft ridge would need to support 840 lbs. If We don't want a post on the main floor, the loft edge joists need to be designed as a beam capable of supporting an 840 lb point load, at midspan.

Just for general knowledge a center point load yields twice the bending moment compared to a uniformly distributed load along a beam's length. Looks like a triple 2x8 floor joist on the loft edges will carry the load and direct the load path to the side walls.

|

|

DRP

Member

|

# Posted: 11 Jan 2026 09:39am

Reply

This is a side shot of the pic above, I was starting to fill in studs. The let-in 2x6 ribbon under the loft joists is there. Follow the ridgebeam load path, down the post at the loft edge, to the triple 2x8 loft edge beam, bridging over to triple studs at each end supporting the loft edge beam, down to the main floor girder. That is an unaccounted ~500lb point load that needs redesign... part of why builders don't do this stuff. Each time you collect and concentrate a new point load onto the main girders they get a new bending stress. The effect is not immediate, I fix a lot of old houses with the wiggles and creeps caused by these "ghost" loads. The jacks on each side of a large header are another way this happens. Keep following the load path to the adjoining posts, you can see the proportion of the load heading for each post and its' footing. Think about this also. Each independent post is carrying a different load, will they cooperate and settle at the same elevation when all is done and loaded.

|

|

DRP

Member

|

# Posted: 11 Jan 2026 11:37am

Reply

In the sketches above I drew in a double 2x12 ridge. Doing the math, with the post there a single 2x12 is sufficient as a ridgebeam, for both spans.

The tributary from the cathedral area is ~2450 lbs loading that 140" span. Let's put half that on the loft post, with the loft ridge load of ~850lbs and check the loft edge beam again.

The old adage "load goes to stiffness"... even with the raised ties I believe we are attracting more load to that ridge and post than the raised tie triangle running it to the eaves... its down in the weeds but when the raised tie rafter couple deflects 3/8" it is hanging on the ridge and it acts as a ridgebeam roof... lets see what that loft edge beam looks like at that 2065 lb point load.

.. a 4 ply 2x10 built up beam at the loft edge works. Flush on the top and lower the studs supporting it 2" below the top edge of the joist ribbon. or a triple 2x12, or hmm, a double 2x8 LVL barely works. A double 2x10 LVL looks very good there.

The rafter ties just became optional.

That added to the main floor girder problem under the stud stacks. I'd widen the footings on those 2 posts on each side and lag a 6x6 short post to the tall post under each end of the main floor girder there.

I did the engineering calcs behind the scenes but the supplier of LVL's and engineered materials can have their techs or engineers do the calculations for you... that is one thing to remember, engineered materials offer engineering for the materials as part of the sale. LVL's, glulam, any of the engineered beams, roof or floor trusses, etc. I can hand them the plans and they come back with their engineered components, stamped by an engineer if the inspector needs. That is the nice thing about using those materials.

Another cite that comes down to common sense. studs... columns of any sort, run unbroken from points of lateral support, typically from floor to floor or floor to roof. There is no weak hinge in the middle of the wall. Yes, a pic of one was posted last week. No one pointed it out but don't copy that. Your tall gable wall is balloon framed with full height studs. Technically it is getting beyond 2x6's... a wall is just a floor standing up, the design load (wind) is more like 20 psf rather than 30 or 40 for floor loads but still significant. Those studs are ~17' right under the peak down to about 11' at the sidewall. We wouldn't think of 2x6 floor spanning 11-17'. Think about how much fetch you have to the wind at that site. I've had 2x8 studs drawn in for studs in that range often.

Going long but that led to thinking about the tall column supporting the ridge at the cathedral gable end. Figuring a 3 pack of studs, the middle one is 17'3" under the 2x12 ridgebeam, the ones on each side are 18' and run along each side of the ridge. A column of that dimension loses 62% of its strength due to slenderness... a short fat column fails by crushing. As they get taller you have to back off of that to avoid a buckling failure. At 17'3 and 5.5" deep you can safely use 38% of crushing strength. And then there's wind wanting to buckle it too, that 2x8 gable stud wall is looking better.

|

|

philpom

Member

|

# Posted: 11 Jan 2026 03:37pm - Edited by: philpom

Reply

FWIW I'll offer what I did for our foundation. The 2 story cabin has been standing for almost 15 years. The cabin is on a slope, 12" off the ground on one side and 8' off the ground on the other. Used tubes 3 feet in the ground on gravel to pour 12" round piers. Used multiple tubes as needed for height of the piers. 25 piers total for a 28'x24' footprint. The piers had hurricane ties set in to the wet cement and the girder beams fastened to those. The tallest row of piers have 6x6 posts due to height requirements.

The girder beams are 2x12 and fully boxed, the joist beams are 2' on center 2x12 and fully boxed. The sub-flooring is 3/4" plywood. All of the lumber is pressure treated. The girders run the 28' span, that the direction of the slope. Liquid nails was used for every union and it was assembled using deck screws. The cabin was built on this.

To code? There is no code where we built but if there was, I have no clue. The most important thing in my mind is that folks do for themselves what they are comfortable with. For some that's relying on specs and for others that's an eyeball and a good feeling of "that'll do fine". I'm in the latter.

Our shed is up top on a pretty level spot, it just sits on blocks with 4x4 girder beams, I'm certain it'll be great for decades. The shed at our primary home is on railroad ties with no girders, it's been up for 50 years....

I hope the OP doesn't suffer paralysis by analysis and gets his place up in a way he sees fit so they can enjoy it.

|

|

TNwoodsman

Member

|

# Posted: 12 Jan 2026 02:47pm

Reply

DRP,

Thank you for your responses.

May I summarize to be sure i understood it all.

I understand most of your terminology...

I can do a single 2x12 ridgebeam.

The gable walls should be framed with 2x8s.

The ridgebeam will be supported on each gable end by 3 2x8s

At the loft edge, I will have 3 2x8s acting as a support column to the ridgebeam or 4 2x10s as support to the ridgebeam?

As I understood you, if I use 4 2x10s then I can eliminate the rafter ties all together? Can you clarify?

Thank you!

|

|

DRP

Member

|

# Posted: 12 Jan 2026 10:57pm - Edited by: DRP

Reply

Yes, a single 2x12 ridgebeam.

The tall gable wall is framed with 2x8's. The loft end is platform framed, 8' studs below and various shorter studs from the loft floor (* a point of lateral support) to roof, another point of lateral support. So at that end we can run 2x6's because they are shorter. In both cases we are running the studs unbroken between points of lateral support, floor planes or the roof plane. (the big word is floor or roof diaphragm)

Ridgebeam support column at the tall wall is a triple 2x8 from main floor to roof diaphragm. At the loft edge the ridgebeam is spliced over/ within a triple 2x6 support yoke that runs from the loft edge beam to ridge. At the loft gable end a triple 2x6 runs from a loft edge beam to the ridge.

At both loft edges and under the tall gable wall there are built up beams. I moved eave wall post spacing, simplifying loft beam support but changing the span of a few beams. At first blush a 4 ply 2x12 as the tall gable wall main floor rim (the wall load plus the ridge column load). At both loft edges a 4 ply 2x10 should work.

The raised ties are optional at that point... nothing wrong with some level of redundancy either and a doubled one or 2 can support lights or fan.

Take a look at it and see if that is on the right track.

One thing I see is with the tall sidewalls, if it were on a flat site a wraparound porch... and then you can close in rooms on the porch.

1420loftedge.jpg

|

1420gable.jpg

|  |  |

|

|

Aklogcabin

Member

|

# Posted: 13 Jan 2026 02:11pm

Reply

Sounds like you're going to have a great cabin TNwoodsman.

|

|

TNwoodsman

Member

|

# Posted: 13 Jan 2026 02:19pm - Edited by: TNwoodsman

Reply

|

|

Aklogcabin

Member

|

# Posted: 13 Jan 2026 02:22pm

Reply

My comments regarding codes. We are not required to have our homes inspected for any code enforcement where we live. I hire an independent home inspector to inspect the homes I build.

Just seems like some folks come here looking for something that they can get into money wise. I think back at Gary Os cabins. There all good. As long as folks can enjoy the cabin life and be reasonably safe. And there is a lot of technical information that a lot of folks can find intimidating.

Sorry if it struck any nerves. Meant as constructive criticism only

|

|

TNwoodsman

Member

|

# Posted: 13 Jan 2026 06:20pm

Reply

I think there is value in all comments as long as it's constructive. Your point was well received. On one hand, im looking for practical information to help me as im not a carpenter by trade nor do I know the technical ins and outs and this is one of those "you dont know what you don't know" kind of deals. It is easy to get overwhelmed and easy to get frustrated. Sometimes im thinking, "man, I just want to build a little cabin, why is this so hard?!"

But I also want to do it at least right enough that it will last and not give me major headaches. And of course not fall down. Im not overly concerned with codes as there are no inspections involved here but I know safe and right intertwine with codes. This build gives me good experience for future builds. I have already learned a lot and I am grateful for the people who have given me feedback whether its been technical code advice or simply "this is what I have done and it worked for me" advice.

Its nice understand the science behind why we build how we build and I appreciate DRP for those lessons and his time.

So thank you everyone for your time and insight. I know I will have more questions as I begin construction hopefully in the coming months.

|

|

DRP

Member

|

# Posted: 14 Jan 2026 07:59am

Reply

The exasperated building inspector took me aside on one job. "Bless his heart, he don't know just how much he don't know  ". ".

This design does not rely on mud to keep it upright. The posts are braced by the sheathed walls. This foundation has costs as well. I did some beam sizing so have a BOM, bill of materials.

8- 6x6 tall posts, look for "UC4" on the tag, ground contact.

3- 2x12x14', tall wall rim

2- 2x10x14, loft end main floor rim

6-2x10x12' & 6-2x10x8', eaves main fl girders

16 HUCQ hangers; https://www.strongtie.com/facemounthangersssl_solidsawnlumberconnector/hucq_hanger/p/ hucq#p_details.

The posts at the loft edge are the most heavily loaded, let's do a load trace.

1/4 of the roof design load - 2400 lbs

1/4 of the loft load -1120 lbs

~50 sf of main floor load- 2500 lbs

Total ~ 6,000lbs

We have to get that safely to earth. Assume 1500 lbs per square foot soil bearing capacity and the footings need to be 2'x2'. Use 18" rebar (steel no closer than 3" to soil) in a # pattern 3" from the bottom of the footing. The thickness of a footing must be at least as much as the projection of the footing beyond the post to avoid "punch through". Make it at least 10" thick. Secure the posts to the footings.

Now look at wind. The eaves wall and roof presents about 400sf to the wind, call it 20 psf of wind pressure. There's about 4 tons trying to knock you over in a gale. Don't skimp on the footings or those connections. Under "bless his heart", I've removed and replaced many broken deck screws, never a nail. We use nails because they are ductile. Brittle failures give zero warning... snap, whump. Ductile failures usually creak loudly and visibly distort prior to collapse. Construction adhesives are not structural, they do make things stiffer but add no bending strength. R602.3(1) is the fastening schedule. It tells what nails to use where. When using proprietary hardware use the manufacturers connection table. For instance those HUCQ hangers will come with structural screws.

|

|

MtnDon

Member

|

# Posted: 14 Jan 2026 09:23am

Reply

|

|

DRP

Member

|

# Posted: 15 Jan 2026 11:01pm

Reply

I've been doodling a little more this evening. I added a porch roof that can be done in up to 4 phases if need arises. I drove by one on the way home tonight that probably started in the 20's and has fully wrapped and enclosed in my time. It is 10' from outside of wall to outside of porch carry beam, enough room for a room on any porch later. I guess my sketch is the beginning of the 3rd phase, a 34' hipped wrap around on one end.

In this view I noticed something. In an earlier frame sketch I had the eave wall roof beams at the top of the posts. In this drawing I have the floor girders on the eave walls sized to support the floor and roof... but the rood load is travelling down the studs to the floor. The studs are structural in that framing configuration. Modifying them requires a header over a new opening in the wall.

If the roof support beams are on top of the posts, the roof load goes across the beams up there, over to the posts and down. The studs between posts are not load bearing in that framing configuration. Opening up walls between posts, at least in the greatroom 2 bays, later is easier if the roof support is up high. If none of this is potential, beams down low is easier framing.

|

|

| << . 1 . 2 . 3 . |